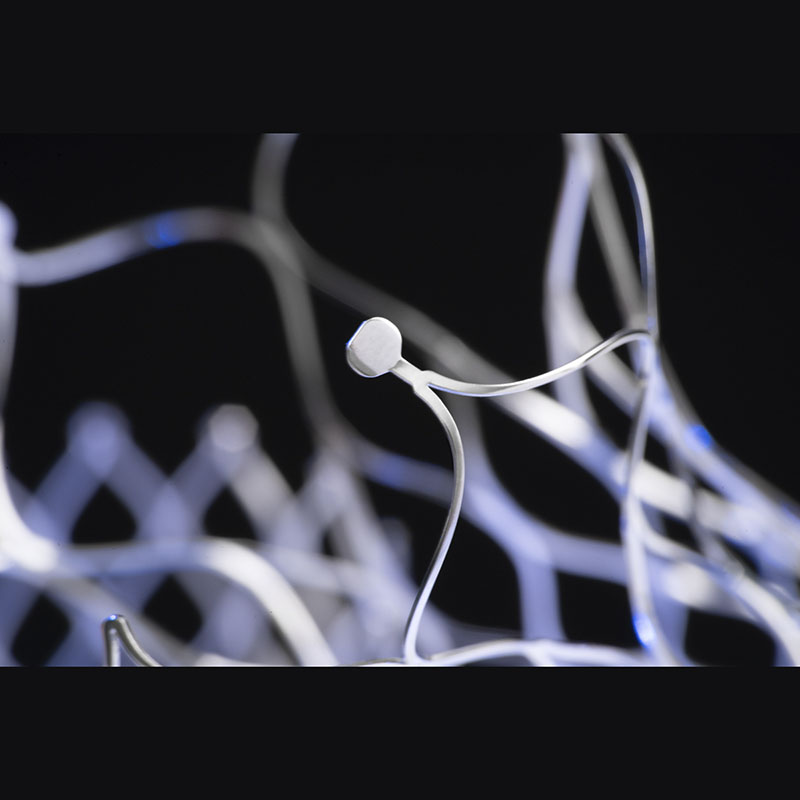

Izingxenye zezokwelapha zensimbi ezinama-nitinol stents & nesistimu yokulethwa kwamakhoyili akhiphekayo

I-Rapid Response Prototyping

Ubuchwepheshe be-Laser

I-Surface Finishing Technology

I-Parylene & PTFE Coating Technology

Ukugaya Iphrofayili Engenasikhungo

Ukushisa Ukuncipha

I-Microassembly

Amasevisi Welebhu Yokuhlola

● Ama-coronary nama-neuro stents.

● Amafreyimu e-valve yenhliziyo.

● Ama-peripheral arterial stents.

● Izingxenye ze-endovascular aneurysm.

● Isistimu yokulethwa kanye nengxenye ye-catheter&.

● Ama-stents e-Gastroenterology.

Ama-Stent & Nitinol Components

| Okubalulekile | Nitinol/Stainless steel/Co-Cr /… |

| Ubukhulu | Ukunemba kobubanzi be-Strut: ±0.003mm |

| Ukwelashwa Kokushisa | Ukwelashwa kwe-oxide emnyama/eluhlaza okwesibhakabhaka/ekhanyayo yezingxenye ze-nitinol Ukwelashwa kwe-vacuum kwensimbi engagqwali nama-Co-Cr stents |

| Surface Finishing | ● I-Microblasting / i-chemical etching and polishing/ Ukupholisha ngomshini ● Kokubili indawo yangaphakathi nangaphandle ingapholishwa ngogesi |

Isistimu yokulethwa

| Okubalulekile | Nitinol/ Insimbi engagqwali |

| I-Laser Cutting | I-Femtosecond OD≥0.2mm |

| Ukugaya | Ama-multi-tapered grinds, ama-taper amade amashubhu nezintambo |

| Ukushisela | I-Laser Welding/Soldering/Plasma Welding Inhlanganisela ehlukahlukene yezintambo/amashubhu/amakhoyili |

| Izigqoko | I-PTFE/Parylene |

I-laser welding

● I-laser welding ezenzakalelayo yemishini yezokwelapha nezingxenye, ubuncane be-diameter yendawo encane kakhulu bungafinyelela ku-0.0030".

● Ukushiselwa kwezinsimbi ezingafani.

Ukusika i-Laser

● Ukucubungula okungenakuxhumana, ububanzi obuncane bokusika ukusika: 0.001".

● Ukucutshungulwa kwezakhiwo ezingajwayelekile, ukunemba kwempinda kungafinyelela kufikela ku-±0.0001".

Ukwelashwa kokushisa

● Izinga lokushisa elinembile lokwelapha ukushisa kanye nokulawulwa komumo kuqinisekisa izinga lokushisa lesigaba elidingwa umkhiqizo, ngaleyo ndlela kuhlangatshezwana nezimfuneko zokusebenza zemishini yezokwelapha efakelwa i-nickel-titanium.

Electrochemical polishing

● Ukupholisha ngaphandle kokuthintwa.

● Ukuqina kwezindawo zangaphakathi nezingaphandle: I-Ra≤0.05μm, iphakeme ngaphezu kwesilinganiso somkhakha ngo-0.2μm.

● Isistimu yokuphatha ikhwalithi ye-ISO13485.

● Ihlonyiswe ngezinto ezithuthukisiwe zokuqinisekisa ukuthi ikhwalithi yomkhiqizo ihlangabezana nezidingo zezinhlelo zemishini yezokwelapha.